G-Lay Graphene Oil Additive

£18.49 Inc. VAT

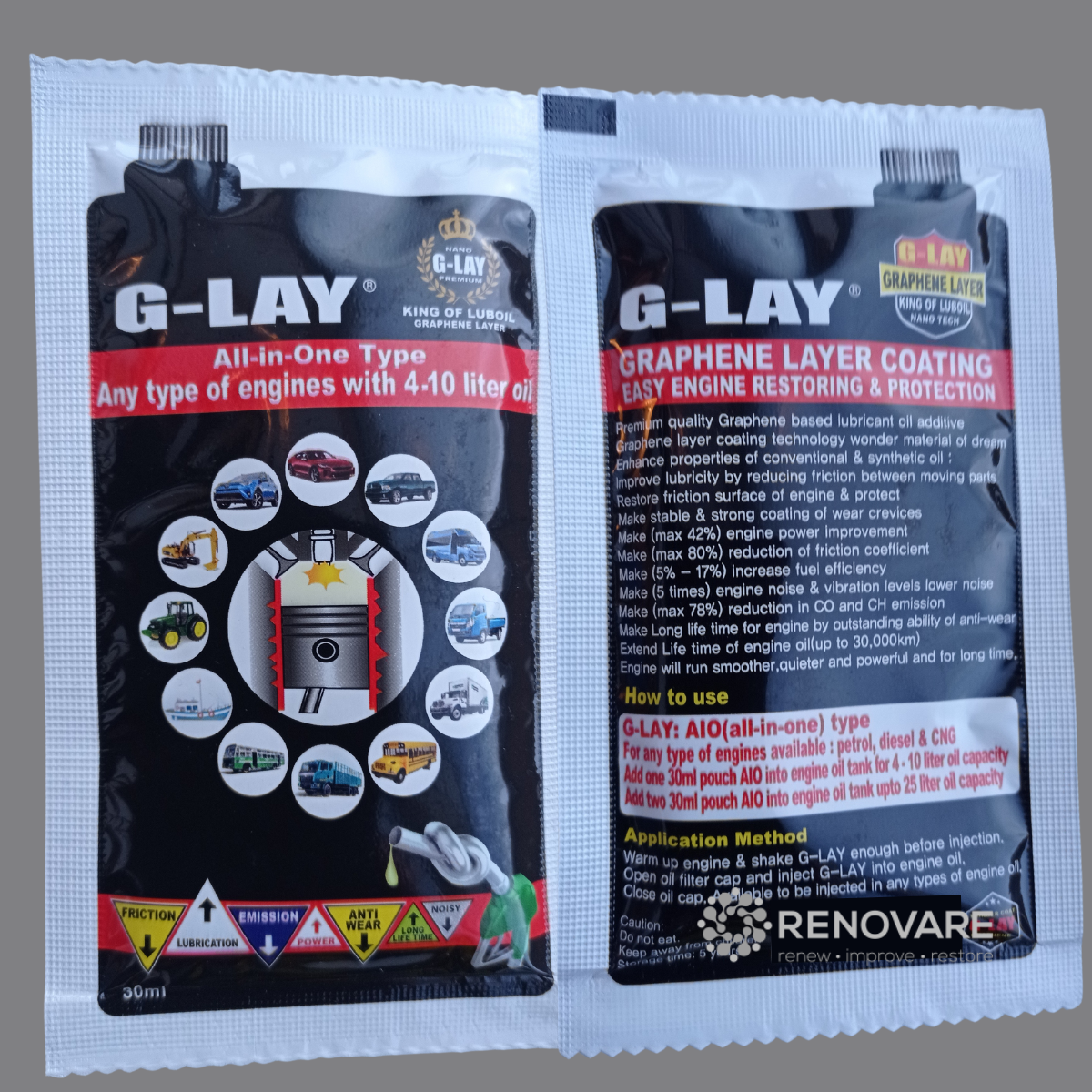

G-Lay (30 ml) is the Ultimate quality Graphene-based oil additive suitable for diesel, petrol or LPG engines with a 4 to 10-litre oil capacity (up to 4000 cc engine).

Any kind of engine, including industrial machinery/equipment that uses an oil reservoir!

This innovative liquid technology coats the engine in a protective graphene layer, restoring the surfaces in the engine and lubricating to protect against all friction wear.

Watch this video – How to Use Nano Technology Products. Please note: Application of Nano Energiser is the same for G-Lay.

Read this article on how it works and how to use it.

All-in-One Type Graphene Oil Additive

Suitable for any type of engine with 4-10 litre oil capacity. Two 30 ml sachets are needed for any type of big engine with 25 litre oil capacity.

Benefits

- Improves engine power by up to 37%

- Reduction friction by up to 75%

- Increases fuel efficiency by 5% to 15%

- Reduces engine noise & vibration by up to 4 times

- Reduces CO and CH emissions by up to 65%

- Extends engine life of the oil (up to 25K miles) due to the amazing antiwear Graphene coating!

- Increases the lifetime of the engine

How do I use G-lay Graphene oil additive?

- Warm up the engine, let it run for a while.

- Shake the sachet vigorously. Cut the corner of the sachet to open the packet.

- Add 30 ml of G-Lay black suspension straight into engine oil.

- Place oil filler cap back.

- Run the engine for a couple of minutes or drive a few kilometers and then the engine is coated with graphene.

How does this G-Lay graphene based oil additive work?

Nanotec International manufactures premium quality reduced graphene oxide (rGO) by chemical exfoliation in the laboratory. The final size of reduced graphene oxide (rGO) is 0.25nm thickness and lateral size 50 nm. This suspension of reduced graphene oxide in mineral oil, mix very well with engine oil. The resulting effect is a nano based graphene coating on the inner metallic side walls or surfaces of the engine. Cracked parts within an engine have a high electric potential and the charged graphene is moved selectively on these metallic surfaces. Cohesion to these inner parts is conducted by heat and pressure. After restoring abrasion parts with this graphene based coating, lubrication properties are enhanced.

Are there any disadvantages of using graphene based oil additives?

No, this product has been manufactured to an optimized particle size (one atom thick) to improve lubrication ability without clogging the oil filter. Graphene is a nano material with exceptional properties i.e., it is not only the thinnest, but also one of the strongest materials, and conducts heat better than all other oils. It restores worn out metallic surfaces by laying a lubrication membrane on friction parts which maximise lubrication abilities.

For best results, change the engine oil before applying this product, or apply it after a service.

Read this article to see how it can reduce CO2 emissions.